Add : No. 58, Peng Qing Road, Guan ng Road subway station, Shanghai Metro Line 11

Chief Engineer :

Roy Li 0086-13310056505

Nancy Jing 0086-13310056506

May Feng 0086-13310056508

Website : www.sinojump.com

Email Address : customer@sinojump.com

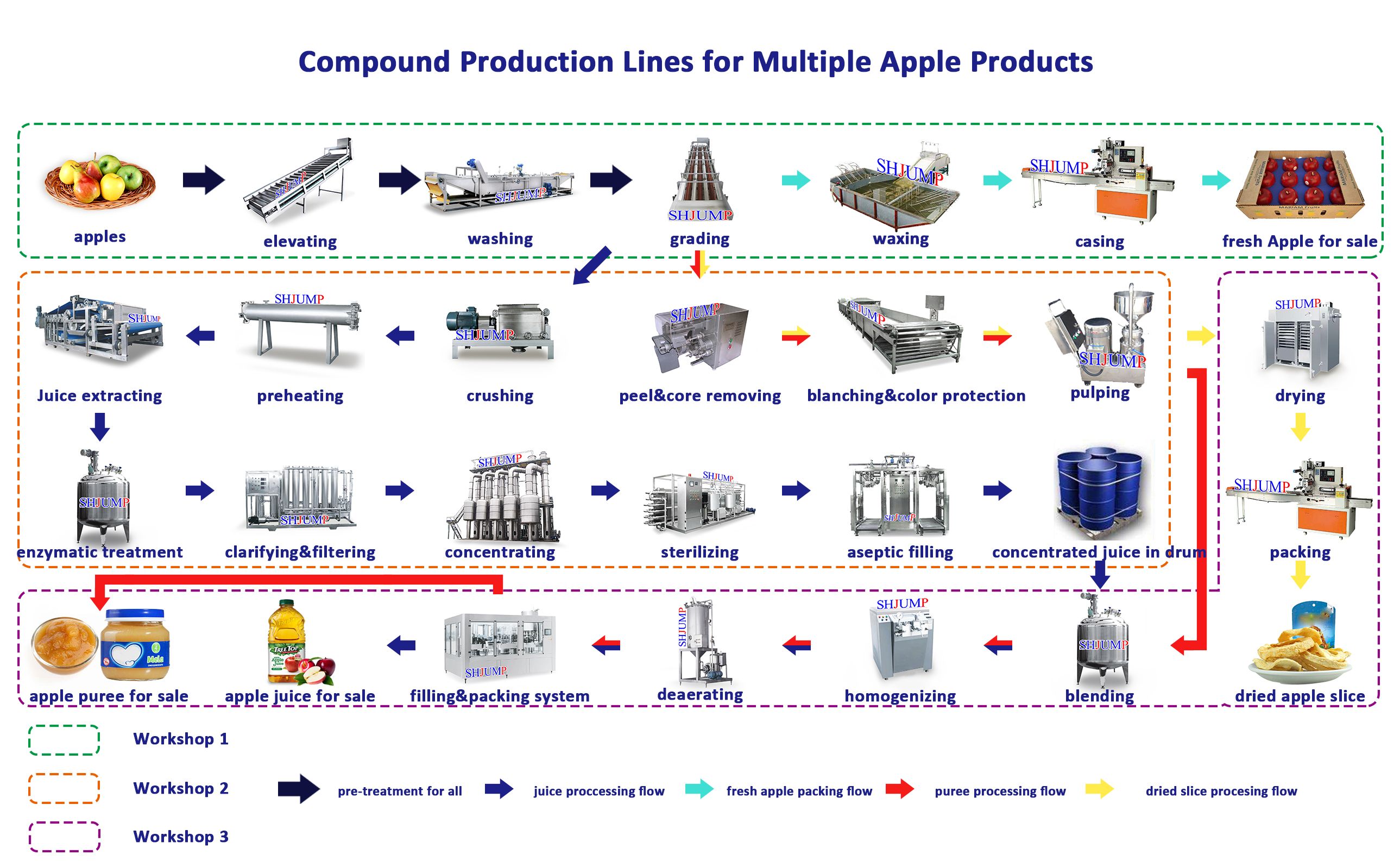

| Raw Material | Apple, pear and similar fruits |

| Final Products | Concentrated Juice, cloudy juice, clarified juice, puree, dried fruit and canned fruits |

| Fruit Brix | 10-12 Brix |

| Concentration Brix | 70-72 Brix |

| Processing Capacity | 60-1500T per day |

| Package | Aseptic bag/tin can/glass bottle/PET bottle |

| Juice yield | 75% raw fruit (25% as waste,peels and seeds) |

|

Please kindly understand that the fruit production line is a highly customized product. Our company is capable to design a processing line with capacity 10T-1500T per day. The machine configuration also will be varied based on the automation degree and the final products type you want to get.Therefore,If you need a quotation proposal from us, please contact our staff and offer the following data to serve you better:

1.What's the estimated capacity? Namely, How many fresh fruits you plan to process per day?

2.What will be the final package of your products? in drum, in tinplate or in pouch or in bulk?Will your products face wholesale market or retail market?

3.When and where you want to start this project?

4.Will this project be cost-oriented or quality-driven? We are the best choice for apple/pear processing in Turnkey Solution! |

Add: No. 58, Peng Qing Road, Guan ng Road subway station, Shanghai 11

Chief Engineer : Nancy Jing 0086-13310056506

Chief engineer: May Feng 0086-13310056508

Chief engineer: Andy Liu 0086-13310056505

Website : www.sinojump.com

Email Address : customer@sinojump.com