Add : No. 58, Peng Qing Road, Guan ng Road subway station, Shanghai Metro Line 11

Chief Engineer :

Roy Li 0086-13310056505

Nancy Jing 0086-13310056506

May Feng 0086-13310056508

Website : www.sinojump.com

Email Address : customer@sinojump.com

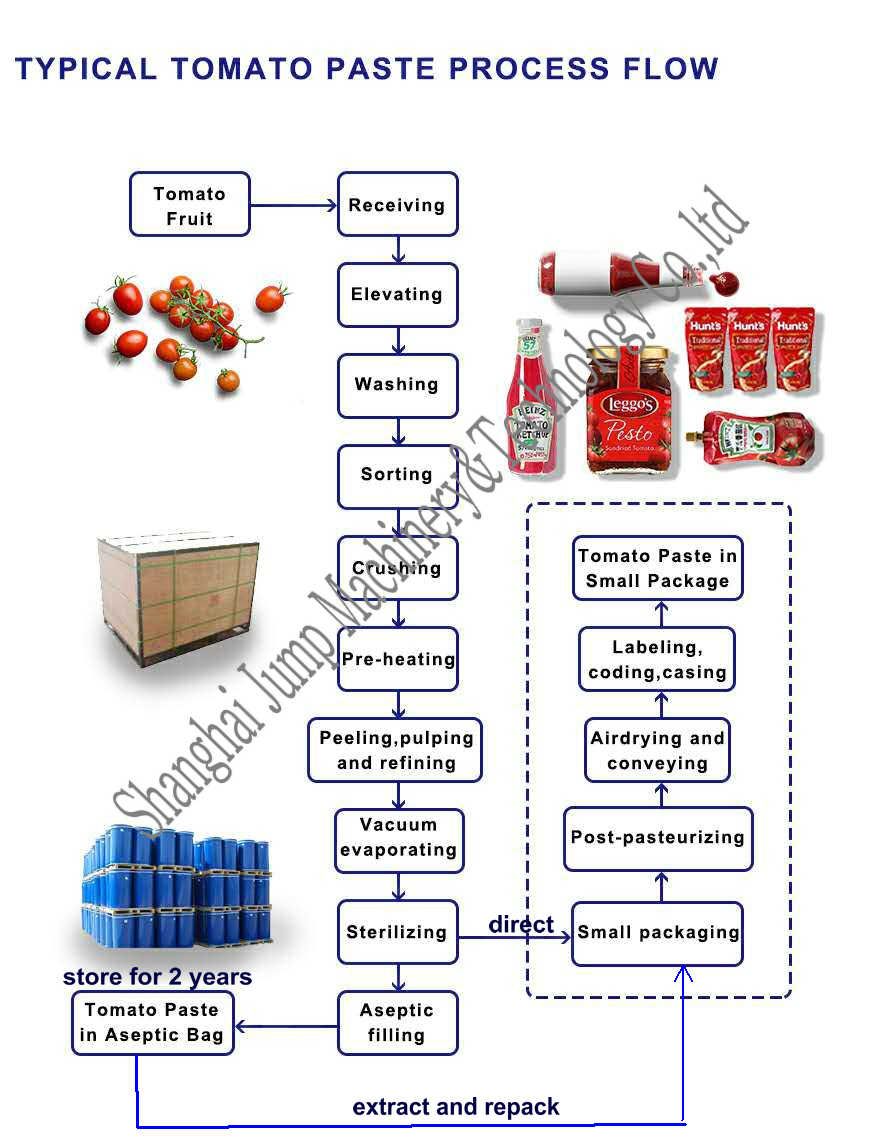

Generally when we talking about tomato paste processing, we mainly means in two ways:

1. tomato concentrate processing line

From fresh tomato To tomato paste concentration 220L aseptic bag in steel drum, including:

fresh tomato lifting syste

cleaning system

sorting system

crushing system

preheating and enzyme deactivation system

pulping and refiningsystem

vacuum concentration system

sterilizing system

aseptic filling system

2.tomato paste dilution and subpacking line:

From tomato paste concentration to jam/paste/sauce/ketchup in pouch/can/bottle etc., including

ingredients preparation system

blending system

homoginizing and deaerating system

sterilizing

filling system

post-sterilizing system

labeling and coding system

enchasing and stocking

Different package for tomato product----- bulk drum, glass, pouch(with or without spout),can or tetra pac etc.

|

please kindly understand that the fruit production line is a highly customized product. Our company is capable to design a processing line with capacity 10T-1500T per day. The machine configuration also will be varied based on the automation degree and the final products type you want to get.Therefore,If you need a quotation proposal from us, please contact our staff and offer the following data to serve you better:

1.What's the estimated capacity? Namely, How many fresh fruits you plan to process per day?

2.What will be the final package of your products? in drum, in tinplate or in pouch or in bulk?Will your products face wholesale market or retail market?

3.When and where you want to start this project?

4.Will this project be cost-oriented or quality-driven? We are the best choice for tomato processing in Turnkey Solution! |

Add: No. 58, Peng Qing Road, Guan ng Road subway station, Shanghai 11

Chief Engineer : Nancy Jing 0086-13310056506

Chief engineer: May Feng 0086-13310056508

Chief engineer: Andy Liu 0086-13310056505

Website : www.sinojump.com

Email Address : customer@sinojump.com