Equipment description

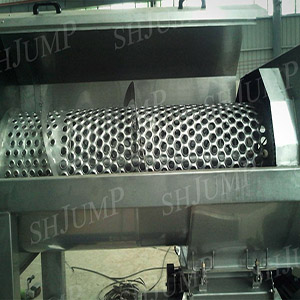

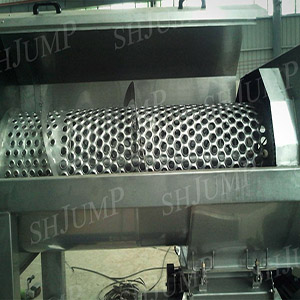

It is ideal for grape fruit stalk separation and crushing, which is the ideal pre-processing equipment for grape winery and grape juice processing plant. The grape stemmer is mainly composed of feeding hopper, except for the stems, the stem shaft, the feeding trough, the crushing device, the frame, the speed regulating motor and the transmission parts.

Working principle

Material into the hopper firstly from the coarse crushing workshop, after coarse crushing studio was broken by the screw conveyor axle to coarse sieve machine, due to the coarse sieve machine rotating unceasingly, makes some finer materials and seeds fall into the segment from the sieve hole sieve beater. The fruit juice is separated from the seeds, the juice is collected from the pulp and the seeds are expelled from the seed hopper. The coarser materials are sent to the fine crushing chamber to further break and improve the juice rate.

Technical parameters

| Product name |

stem removing machine |

| Model |

jpwm-1000 |

| Main material |

food grade SUS304 high quality stainless steel (or customized according to customer requirements) |

| Processing capacity |

0.5 tons per hour to 15 tons/hour (or customized according to customer requirements) |

| Specification |

based on the capacity and user requirement |

| Application |

to remove the stem for grape, raisins, cherries, etc |

Characteristics of the equipment

1. Spiral quantitative feeding. Break after the stem.

2. The removal of the stem shaft and the removal of the terrier can achieve stepless speed regulation. The length of the trabecter is longer, which can be adapted to the treatment of many varieties of grapes, with less fruit stalks in the outside of the machine.

3. The products are made of high quality stainless steel. The crushing device is located in the lower part of the screen and the crushing roller is made of high elastic and non-toxic rubber. The crushing device is connected with the body in a quick way.

4. The slurry pump is installed on the lower part of the crushing device for a single screw pump.

Contact Us

Email address: customer@sinojump.com

Chief engineer: Nancy Jing 0086-13310056506

May Feng 0086-13310056508

Andy Liu 0086-13310056505

Leave a message